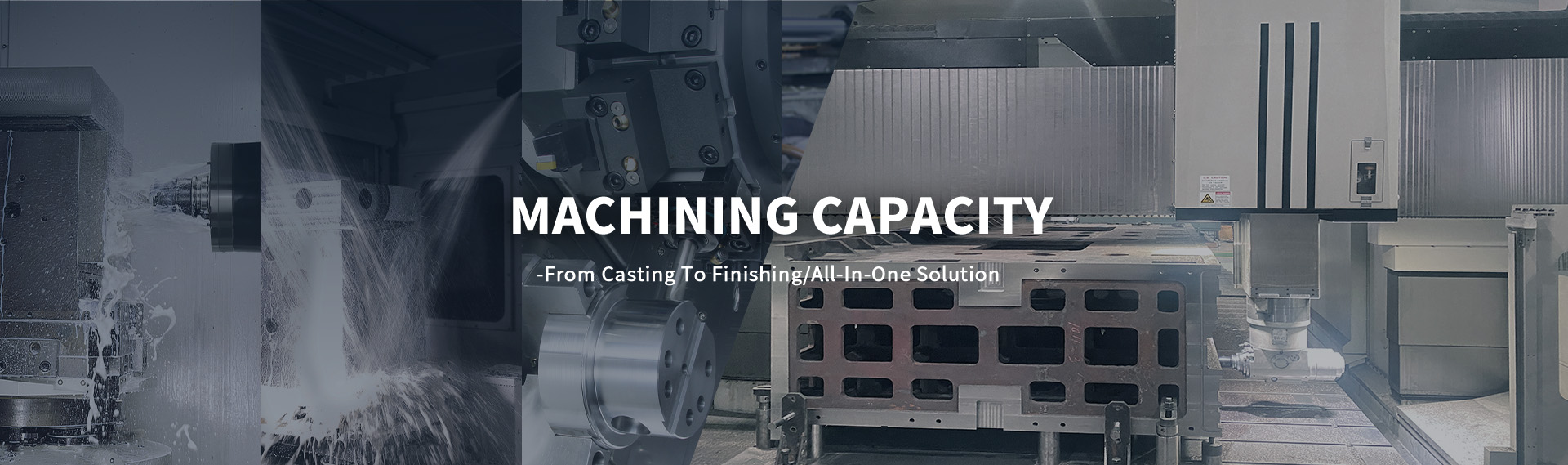

Machining Capacity

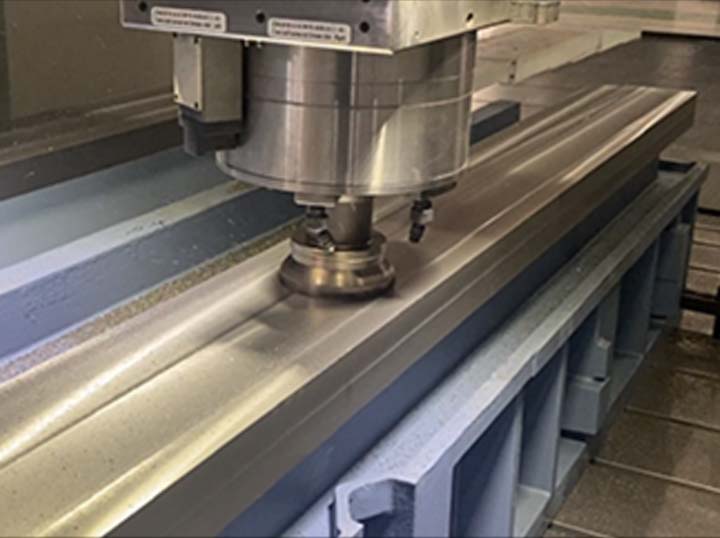

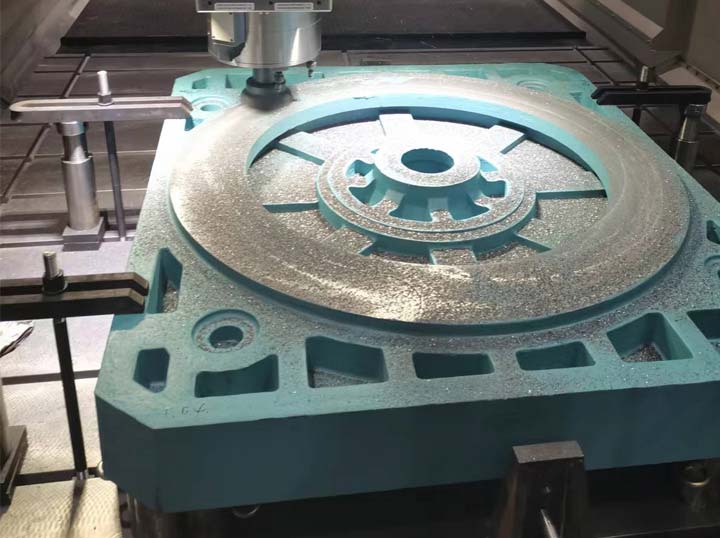

The company has introduced various types of imported high-precision mother machines according to the requirements of our customers. We can provide with one-station solutions from casting to rough and finishing machining. The constant-temperature machining workshop is equipped with 8-meter Japanese portal milling machining center, 8-meter high-precision grinder, high-frequency quenching machine, horizontal machining center, CNC lathe, etc.